StudySmarter - The all-in-one study app.

4.8 • +11k Ratings

More than 3 Million Downloads

Free

Americas

Europe

Enzymes are biological catalysts that speed up chemical reactions without causing lasting changes. They do this by lowering the activation energy needed for the chemical reaction to take place. Enzymes function both intracellularly and extracellularly in living organisms. Let's dive into enzyme-controlled reactions.

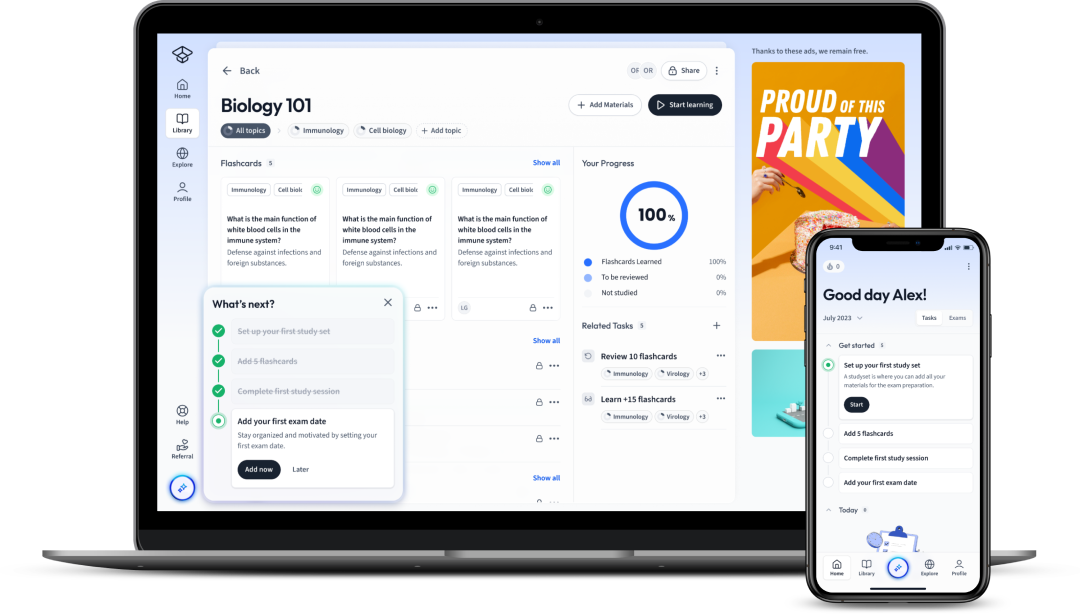

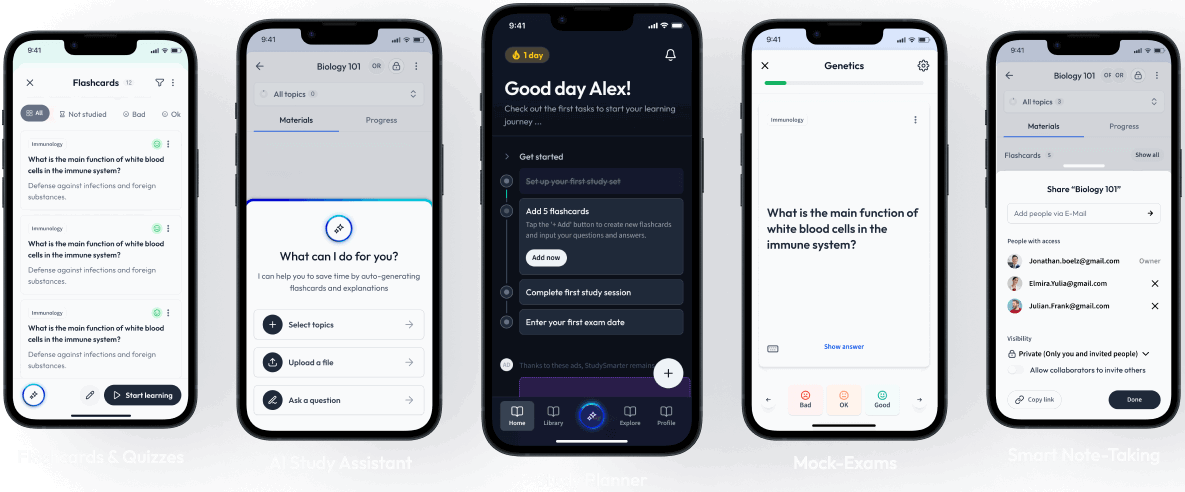

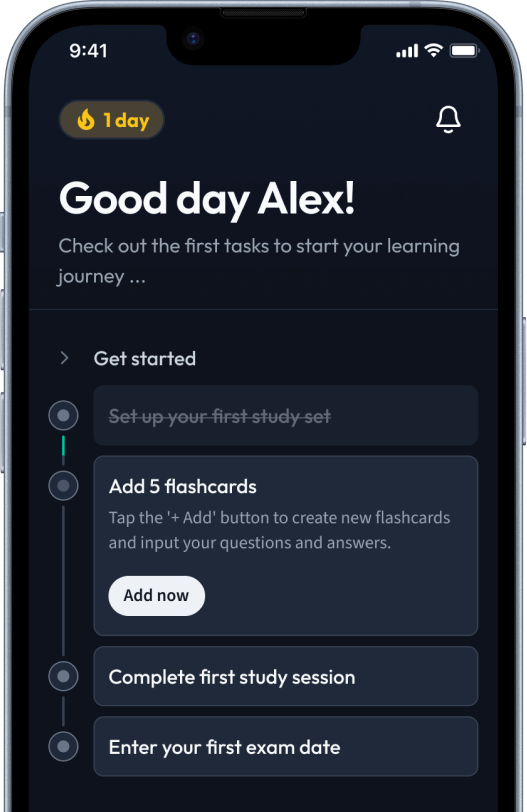

Explore our app and discover over 50 million learning materials for free.

Lerne mit deinen Freunden und bleibe auf dem richtigen Kurs mit deinen persönlichen Lernstatistiken

Jetzt kostenlos anmeldenEnzymes are biological catalysts that speed up chemical reactions without causing lasting changes. They do this by lowering the activation energy needed for the chemical reaction to take place. Enzymes function both intracellularly and extracellularly in living organisms. Let's dive into enzyme-controlled reactions.

Catalysis - the process by which a catalyst (e.g., enzymes) increases the reaction rate.

Activation energy - the minimum energy needed to initiate a specific reaction.

There are two main types of enzyme-controlled reactions:

Anabolic (making large new molecules)

Catabolic (breaking a larger molecule into smaller molecules)

The International System for units (SI) is in katal for enzyme activity. 1 katal = 1 mol s-1. However, this is way too high to measure the activity, so usually, 1 μmol min-1 (16.67 (2 d.p.) katal) is used instead.

When a unit is rounded, it is usually to significant figures (s. f.) or decimal places (d. p.).

For example, you have a number - 0.0055834. What will it be to 2 decimal places, and what will it be to 2 significant figures?

Always round up if the number is more than 5; for example, 0.05 will become 0.1 (if 1 d. p. needed). Always round down if lower than 5; for example, 0.14 will be 0.1 (1 d. p.).

An enzyme unit is the amount of enzyme required to catalyse the transformation of 1 μmol of substrate per minute under specified pH and temperature conditions. The number of units per milligrams of protein catalysed represents an enzyme's specific activity.

The following methods can be used to track the progress of enzyme-catalysed reactions:

Calculating the rate at which a product is formed - the rate at which, using the substrate, a new product will be formed.

Calculating the rate at which a substrate vanishes - the rate at which a specific amount of substrate will be used up.

Different factors can influence the rate of reaction, and these include:

Temperature: with increasing temperature, the enzyme activity increases due to increased collisions between the molecules. However, too high of a temperature can cause an enzyme to denature.

pH: different enzymes have different optimum pH levels that they can work best in. Changes in pH outside the optimum range can denature an enzyme.

The concentration of the substrate: more substrate will equal more collisions with the enzyme; however, the rate does not continue to increase exponentially unless there is an unlimited number of enzymes. When all enzyme active sites are occupied, no more substrates can bind.

The concentration of the enzyme: increasing the concentration of the enzyme will increase the rate of reaction up to a certain point unless there is an unlimited supply of substrate. When all substrate has been reacted with, the enzyme has nothing else to bind to.

Presence of inhibitors: inhibitors can either inhibit the enzyme's active site (substrate cannot bind) or bind to the allosteric site (changes the active site).

Enzyme activators: specific molecules that bind to enzymes to increase their activity.

Denaturation: the process by which a protein loses its shape (changes in 3D/tertiary structure) and will no longer bind substrate effectively. This is because the active site has been altered.

Enzyme active site: a specific binding site for the substrate.

Allosteric site: a region of the enzyme where a molecule can bind and alter the active site.

You will find a more detailed explanation for the factors affecting enzyme activity in our Factors Affecting Enzyme Activity article.

Let's have a look at some examples of practicals you may encounter.

In this practical, the rate of reaction of an enzyme-controlled reaction will be investigated using a powdered milk suspension. The independent variable on this occasion will be temperature.

Independent variable: a variable that is not affected by other variables.

Dependent variable: a variable that you are measuring and is influenced by the independent variable.

For this practical, you will need:

Powdered milk suspension

Trypsin solution (0.5 %)

Distilled water

Hydrochloric acid (HCl) (0.1 M)

You will use a variety of conical flasks, tubes and other equipment as needed. Your teacher will provide these.

Trypsin is an enzyme that aids with digestion. For this practical, trypsin will be the catalyst.

First, we need to create our control and test solutions.

Making up control samples

Make two control samples using the steps below. These control samples will be used to compare to your test samples.

Making up test samples and measuring the rate of reaction

The goal is to measure the reaction rate; we will do this by timing how long it will take for the enzyme to affect the reaction at different temperatures. When all protein in the milk has reacted, the solution will become colourless.

So why does the milk go colourless? Milk contains casein which is a slow-digesting dairy protein. When casein is broken down by trypsin, it causes the milk to lose its colour.

As the temperature increases, molecules will move faster due to increased kinetic energy, which will allow more collisions between enzymes and substrates. However, if the temperature is too high, it will cause the enzyme to denature.

To help with data-keeping, we suggest you use the following table arrangement:

Temperature (ºc) | Time taken for casein to break down (s) | Mean time (s) | Rate (s-1) | ||

10 | Repeat 1 | Repeat 2 | Repeat 3 | ||

20 | |||||

You will have three repeats for each temperature (you can have more if you prepare more test tubes). By adding and dividing the time by the number of tubes, you will calculate the mean time taken for the sample to hydrolyse.

Now that you have timed all the reactions, you can calculate the rate of reaction using the following equation:

Rate of reaction = 1 / mean time

For example, at 10ºc, the milk hydrolysed in 50s, 55s and 60s. This means, the mean time is (50 + 55 + 60) / 3 = 55s.

Let's put this into the rate of reaction equation:

1 / 55 = 0.02 (2 d. p.) s-1.

When you calculate rates of reactions for each temperature, you can plot them on the graph to visualise the reaction rates.

Enzymes require a specific pH to work best. Enzymes have a narrow range, and the optimum activity will be at the highest rate. This practical will investigate the optimum pH for the amylase enzyme.

Amylase is a catalyst for the hydrolysis of starch (amylose) to maltose. It is mostly present in plant tissue, which includes seeds. Starch will be broken down during seed germination to release glucose, a food source for the growing seed. Amylase works best at a neutral pH of 7 and a temperature of 37 ° C.

Changing different independent variables, such as the pH or concentration of the enzyme or substrate, will allow you to investigate their effects on reaction rate.

Another enzyme you could potentially use is pepsin. Pepsin is an enzyme that catalyses the breakdown of proteins. Pepsin is present in most animal stomachs, and unlike most enzymes, its optimum pH is very low. This means it thrives in acidic environments.

During cellular respiration, your mitochondria produce hydrogen peroxide (H202) as a by-product of oxygen combustion (substances react with oxygen to give off heat). Hydrogen peroxide is toxic to cells, so how does the body get rid of it to avoid harm? Several enzymes, including catalase, break down hydrogen peroxide. When it is broken down, it produces oxygen and water.

In this practical, you will investigate how different concentrations of hydrogen peroxide affect oxygen production.

Increasing the concentration of hydrogen peroxide, i.e., the substrate will increase the reaction rate. However, this will not go on forever (unless an unlimited amount of enzyme is available), so when all enzyme active sites are occupied, no more substrate can be converted.

Another factor affecting the reaction rate is enzyme concentration. The more enzymes you have, the quicker the reaction rate until all active sites are occupied. In this practical, you will measure the absorbance using a colourimeter (measures light transmittance).

Milk powder solution

Trypsin solution (1%)

Distilled water

Dilute the stock trypsin solution to produce concentrations of 0.2, 0.4, 0.6 and 0.8 %.

In the control solution, add 2cm3 of stock trypsin (1%) and 2cm3 of distilled water. This solution will be used to set the absorbance to zero.

In your test solution, add 2cm3 of milk suspension and 2cm3 of stock trypsin (1%). Mix and place in the colourimeter to read the absorbance.

At regular 15 second intervals, record the absorbance reading. Do this for 5 minutes.

Now repeat this for the other trypsin concentrations.

You can use the rate of reaction formula in the previous section to calculate the reaction rate.

The initial reaction rate will be directly proportional to the concentration of the enzyme. If unlimited substrate was present as the enzyme concentration increases, this increase could continue forever!

When you plot the enzyme concentration against the reaction rate with your result, the points may not totally fall in a straight line. However, in the perfect world, this is how it will look (Figure 3).

When there is a limitation in enzyme concentration, the reaction will initially increase until all enzymes are occupied. It will reach the plateau (a flat line at a specific reaction rate).

An increase in substrate concentration will increase the rate of reaction, then it will plateau. The plateau occurs when all the enzyme active sites are occupied.

The optimum pH will be different for each enzyme. Any variation in the optimum pH will reduce the rate of reaction and can also denature enzymes. This is because the amount of H+ ions will affect the tertiary structure, and therefore the active site of the enzyme.

Enzymes can be tested using different experiments.

For example, the effect of pH on enzymatic rate can be tested by placing enzymes in different concentrations of acid/alkaline solutions.

Enzyme controlled reactions can be controlled by factors such as:

Enzyme activity can be affected by factors such as temperature, pH, and enzyme concentration.

Two main kinds: anabolic and catabolic.

The first learning app that truly has everything you need to ace your exams in one place

Sign up to highlight and take notes. It’s 100% free.

Save explanations to your personalised space and access them anytime, anywhere!

Sign up with Email Sign up with AppleBy signing up, you agree to the Terms and Conditions and the Privacy Policy of StudySmarter.

Already have an account? Log in