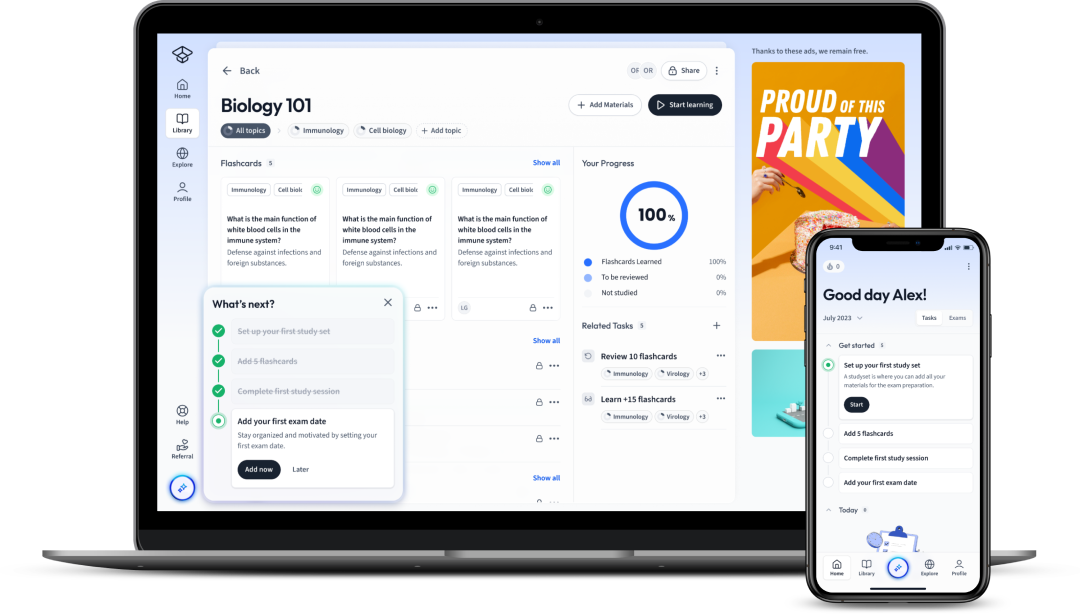

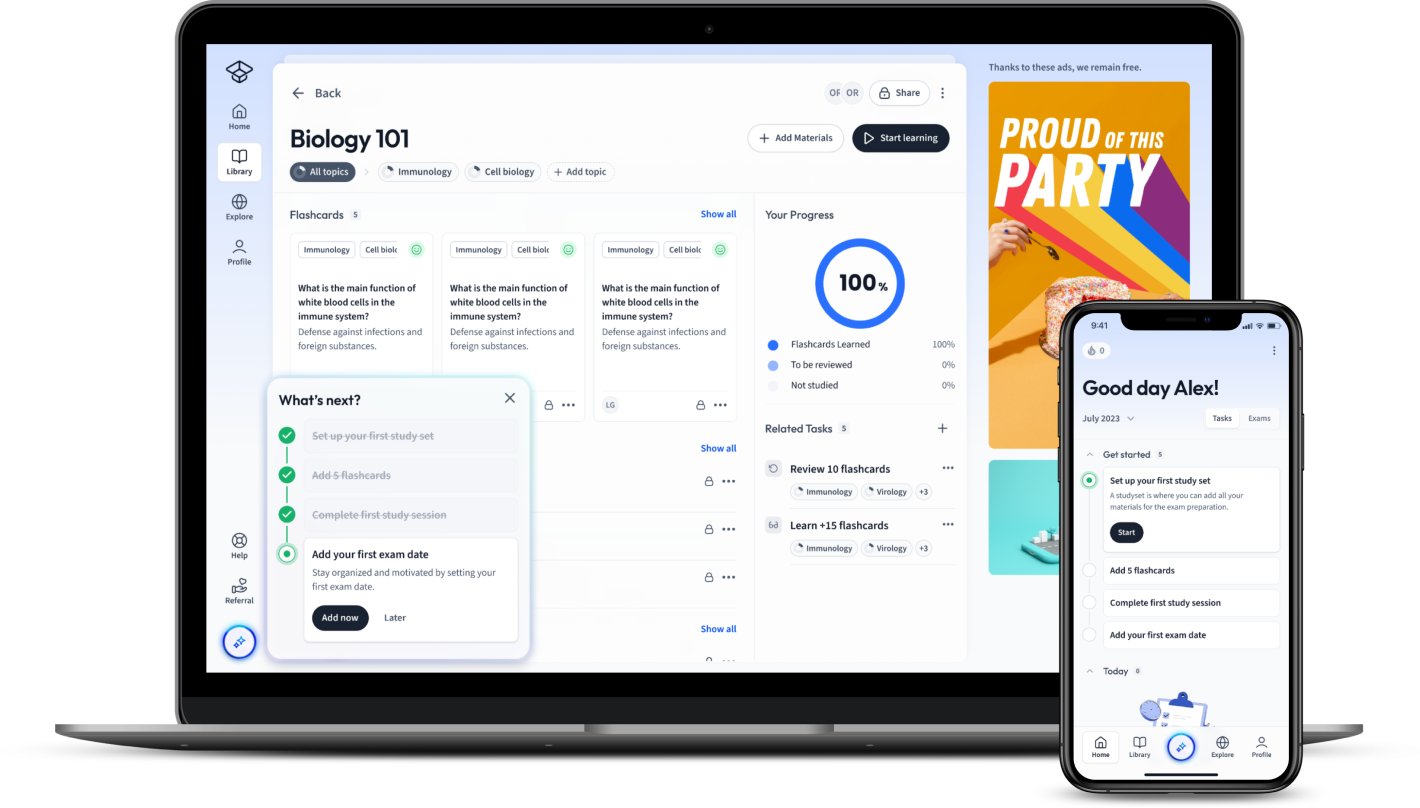

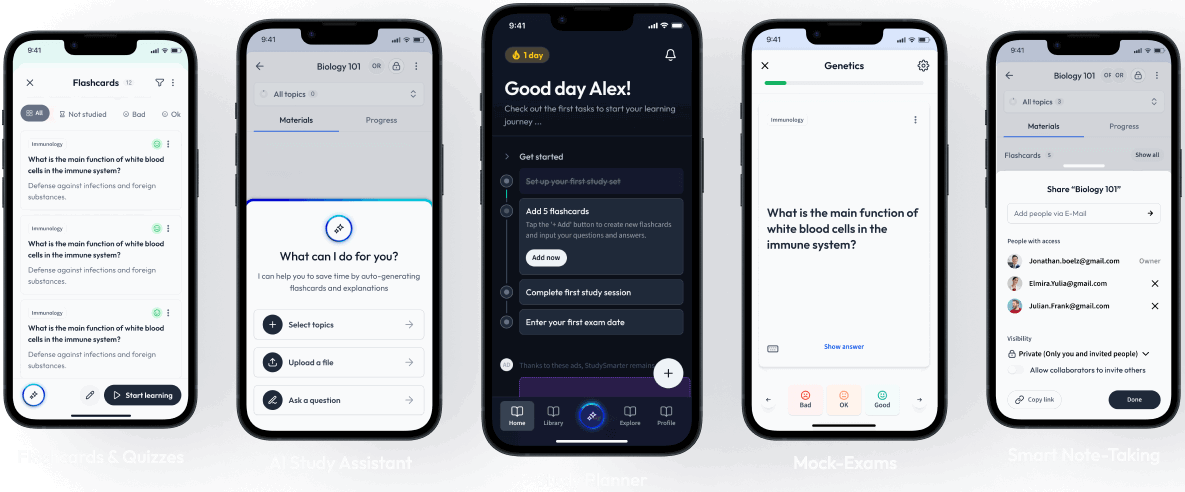

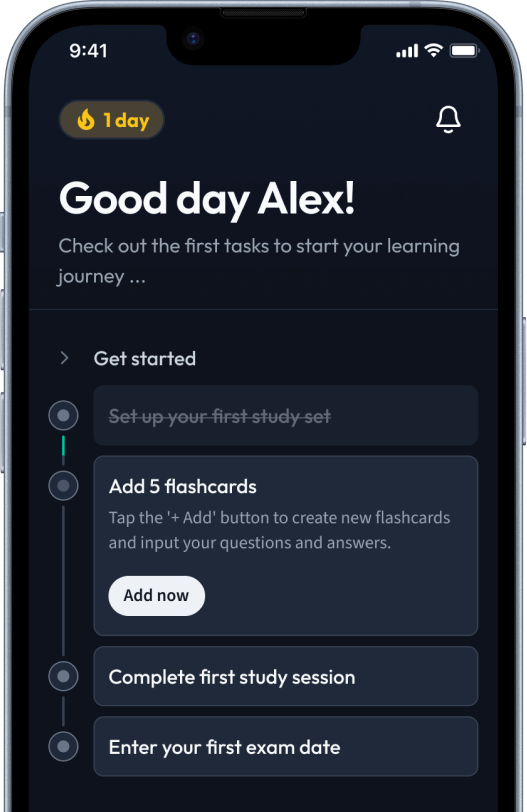

StudySmarter - The all-in-one study app.

4.8 • +11k Ratings

More than 3 Million Downloads

Free

Americas

Europe

Risks and costs are on the opposite end of the inventory management spectrum. A focus on cost reduction will increase the risk of stock-out and production inefficiencies, whereas more risk management results in higher inventory costs. When a company prioritises risk reduction over costs, it is likely to adopt Just-In-Case inventory management. What is Just-In-Case production and how does it work? In today’s explanation, you will find out.

Explore our app and discover over 50 million learning materials for free.

Lerne mit deinen Freunden und bleibe auf dem richtigen Kurs mit deinen persönlichen Lernstatistiken

Jetzt kostenlos anmeldenRisks and costs are on the opposite end of the inventory management spectrum. A focus on cost reduction will increase the risk of stock-out and production inefficiencies, whereas more risk management results in higher inventory costs. When a company prioritises risk reduction over costs, it is likely to adopt Just-In-Case inventory management. What is Just-In-Case production and how does it work? In today’s explanation, you will find out.

To ensure there’s always stock available when needed, companies often employ Just-In-Case inventory management.

Just-In-Case (JIC) inventory management is the technique of keeping a lot of stock on hand to reduce the risk of stock-out.

A company's production is closely tied to its inventory. A low level of inventory puts a business at risk since it might run out of raw materials for production, resulting in a loss of sales. Just-In-Case inventory management maintains stock at a higher level so that there is no disruption in production and products are delivered on time. In case of sudden demand increases, a large inventory also allows the business to produce more goods and generate more income.

JIC is often used for products with a large, ongoing demand. For example, medicines at hospitals are made with the JIC production to meet the constant need of patients.

The opposite strategy of just-in-case inventory management is Just-In-Time (JIT) inventory management. This is the strategy where the business minimises costs and waste by holding just enough inventory for production.

To learn more about JIT and how it differs from JIC, check out our explanation on Just-In-Time Production.

The main purpose of JIC is to reduce the risk of stock-out due to unreliable suppliers, natural disasters, or poor transportation systems. It also saves the company from penalties for late deliveries and loss of sales.

To ensure stock availability, JIC companies have to reorder the stock before it reaches the minimum level. The reorder point should cover enough stock for production while waiting for the new order to arrive. It is calculated by multiplying the average daily usage with the lead time, plus safety stock.

Lead time is the number of days between ordering and receiving inventory. Safety stock is the excess inventory to avoid stock running out completely.

For example, a fashion store re-sells T-shirts from a wholesaler. The daily sales are 100 T-shirts and the lead time is 3 days. The shop also keeps a safety stock of around 50 T-shirts. What is the reorder point for the shop?

Reorder point = (100 x 3) + 50 = 350 (T-shirts)

When the inventory of T-shirts drops to 350 units, the company should reorder a new batch.

The optimal quantity of inventory to minimise ordering and holding costs is called Economic Order Quantity (EOQ). It can be calculated with the following formula:

Where:

D is the Demand for the period

S is the Cost of planning an order

H is the Holding cost per unit

In Figure 1, you can see the Saw-Tooth Inventory Diagram that depicts the reorder point, lead time, order quantity, and safety stock.

Initially, it starts with the maximum level of inventory, which decreases over time as the business sells its products. To avoid stock running out, the company has to place a new order before the inventory reaches the minimum level - the lowest level of stock to be kept at all times, also known as safety stock. The reorder point takes into account the amount of stock needed for production while waiting for the new batch of goods to arrive. It is calculated by multiplying the lead time with the average daily usage.

JIT keeps the supply chain as lean as possible, meaning to produce goods with the least inventory and waste. However, this approach is not very responsive to changes. For example, in the case of a natural disaster or a sudden spike in demand, the low level of inventory in the JIT system will not be able to sustain production. This results in late deliveries and even loss of sales.

To avoid such risks, businesses can adopt the JIC system. JIC piles up stock in advance so that there are always goods available when needed. It is also useful when companies have a hard time forecasting sales or changes in demand. With buffer stock, the business can be more responsive to external influences. However, higher inventory will incur more storage costs and waste.

There are both pros and cons associated with JIC:

Just-In-Case emphasises the importance of having a lot of stock in reserve. This can bring about many advantages for both manufacturers and consumers:

Lower risk of stock-outs: Late deliveries or a sudden surge in demand can cause a shortage in stock. Without excess inventory, businesses run the risk of not having enough raw materials for production. JIC is one way to keep buffer stock and allows the production to run smoothly without disruption.

More flexibility to meet customer demand: Businesses with JIC adapt to abrupt changes in customer demand. For example, an ice-cream business with surging sales in the summer months can place a larger quantity of ice cream cones and other ingredients to keep up with production.

Higher customer satisfaction: Having more inventory means that the business can produce and deliver goods to customers more quickly. This can contribute to a higher level of customer satisfaction.

Lower ordering costs: By keeping a large inventory of goods, the company can place new orders less frequently and reduce ordering costs.

Bulk purchase discount: Businesses can negotiate lower prices per unit with a large quantity ordered, leading to purchasing economies of scale.

While keeping a lot of stock allows businesses to produce goods quickly and meet the demand, it can give rise to many inventory issues.

Higher storage space: A large inventory means a lot of storage space is needed. This can incur more inventory costs for the businesses.

A higher amount of cash tied up to stock: With JIC, businesses need to set aside a substantial amount of cash to pay for suppliers. This may result in a lack of capital to invest in other projects.

Loss of freshness: JIC production can’t be applied to the production of perishable goods such as fruits, produce, or meat since these ingredients will lose their freshness if kept in stock for too long.

Risk of inventory waste: Unsold goods become waste that needs to be disposed of. Since most discarded goods end up in landfills or incinerators, this can cause a lot of environmental issues.

Neither just-in-case nor just-in-time inventory management methods are not perfect, as the reduction of the inventory risks or the reduction of costs tends to come at the expense of the other. A business can maximise benefits by combining the two strategies in a hybrid model - to adopt JIC or JIT whenever it sees fit.

JIC can be applied to products that have a high sales volume and constant demand. Meanwhile, items that are less popular and often sold in small batches can be managed with a JIT system.

The company can adopt a JIT system in the production of personalised pens, as the pens are made to order and the order quantity is quite small. Nevertheless, JIC can be used to keep a large stock of pens waiting to be imprinted.

The adoption of the hybrid model and Just-In-Case and Just-In-Time inventory management requires accurate demand forecasts, as these will allow the business to order a low enough inventory to save costs of continued production.

In conclusion, Just-In-Case is an effective inventory management method to help businesses to cope with sudden changes in demand and avoid stock-out. However, it also comes with the risk of higher storage expenses and waste of unused inventory. One way to adopt JIC with fewer costs and waste is to combine it with the JIT inventory management system. JIC can be used for high-demand items, whereas JIT is typically adopted for lower-demand, made-to-order products. A more accurate demand forecast is key to the success of this hybrid model.

To ensure stock availability, JIC companies have to reorder the stock before it reaches the minimum level.

The reorder point, lead time, and order quantity used in JIC inventory management are depicted in the Saw-Tooth Inventory Diagram.

The main advantages of JIC include lower risk of stock-out, higher customer satisfaction, lower ordering costs, bulk discount purchases, and more flexibility in production.

The disadvantages of JIC include higher storage space and costs, loss of goods' freshness, risk of potential waste, and high amount of cash tied up in inventory.

Just-In-Case (JIC) inventory management is the technique of keeping a lot of stock on hand to reduce the risk of stock-out. Just-In-Case inventory management maintains stock at a higher level so that there is no disruption in production and products are delivered on time. In case of sudden demand increases, a large inventory also allows the business to produce more goods and generate more income.

Examples of JIC inventory can be hospitals. Hospitals store a large supply of medicines and other medical supplies, due to the nature of demand in a hospital.

Higher storage space, higher amount of cash tied up for stock, loss of freshness, and risk of inventory waste are the disadvantages of just-in-case inventory management.

The main purpose of JIC is to reduce the risk of stock-out due to unreliable suppliers, natural disasters, or poor transportation systems.

JIC companies have to reorder the stock before it reaches the minimum level. The reorder point should cover enough stock for production while waiting for the new order to arrive. It is calculated by multiplying the average daily usage with the lead time, plus safety stock.

Reorder point = (Average daily usage x Lead time) + Safety stock

Lead time is the number of days between ordering and receiving inventory. Safety stock is the excess inventory to avoid stock running out completely.

Flashcards in Just-In-Case Inventory Management25

Start learningWhat is Just In Case inventory management?

Just-in-case (JIC) inventory management is the technique of keeping a lot of stock on hand to reduce the risk of stock-out.

What are the benefits of JIC?

Higher customer satisfaction

Why does a company adopt JIC inventory management?

To avoid the risk of stock-out when the demand suddenly increases

What is the diagram that depicts the reorder point for a company's product?

The Saw-Tooth Inventory Diagram

What can be observed from the Saw Tooth Inventory Diagram?

What is the main difference between the JIC and JIT inventory management?

Just In Time aims to minimise costs and waste by keeping little or no inventory whereas Just In Case tries to avoid the risk of running out of stock by keeping a large inventory.

Already have an account? Log in

Open in AppThe first learning app that truly has everything you need to ace your exams in one place

Sign up to highlight and take notes. It’s 100% free.

Save explanations to your personalised space and access them anytime, anywhere!

Sign up with Email Sign up with AppleBy signing up, you agree to the Terms and Conditions and the Privacy Policy of StudySmarter.

Already have an account? Log in